Kreg Jig Cabinet Door Hinge Installation

The Kreg Jig Cabinet Door Hinge Jig simplifies the process of installing cabinet door hinges, ensuring accuracy and consistency. This guide provides a detailed, step-by-step approach to installing various hinge types using the Kreg Jig, highlighting crucial steps and common pitfalls to avoid.

Kreg Jig Cabinet Door Hinge Installation: A Step-by-Step Guide

The following table Artikels the step-by-step process of installing cabinet door hinges using the Kreg Jig. Accurate hinge placement is critical for proper door alignment and functionality. Each step is crucial for a successful installation.

| Step | Image Description | Description | Important Considerations |

|---|---|---|---|

| 1. Prepare the Door | An image showing a cabinet door with the hinge location marked using a pencil and measuring tape. The Kreg Jig is shown positioned for drilling. | Carefully measure and mark the hinge locations on the cabinet door, ensuring even spacing and alignment with the cabinet frame. Use the Kreg Jig’s template to precisely mark the hinge cup locations. | Accurate measurements are paramount. Double-check all measurements before drilling. |

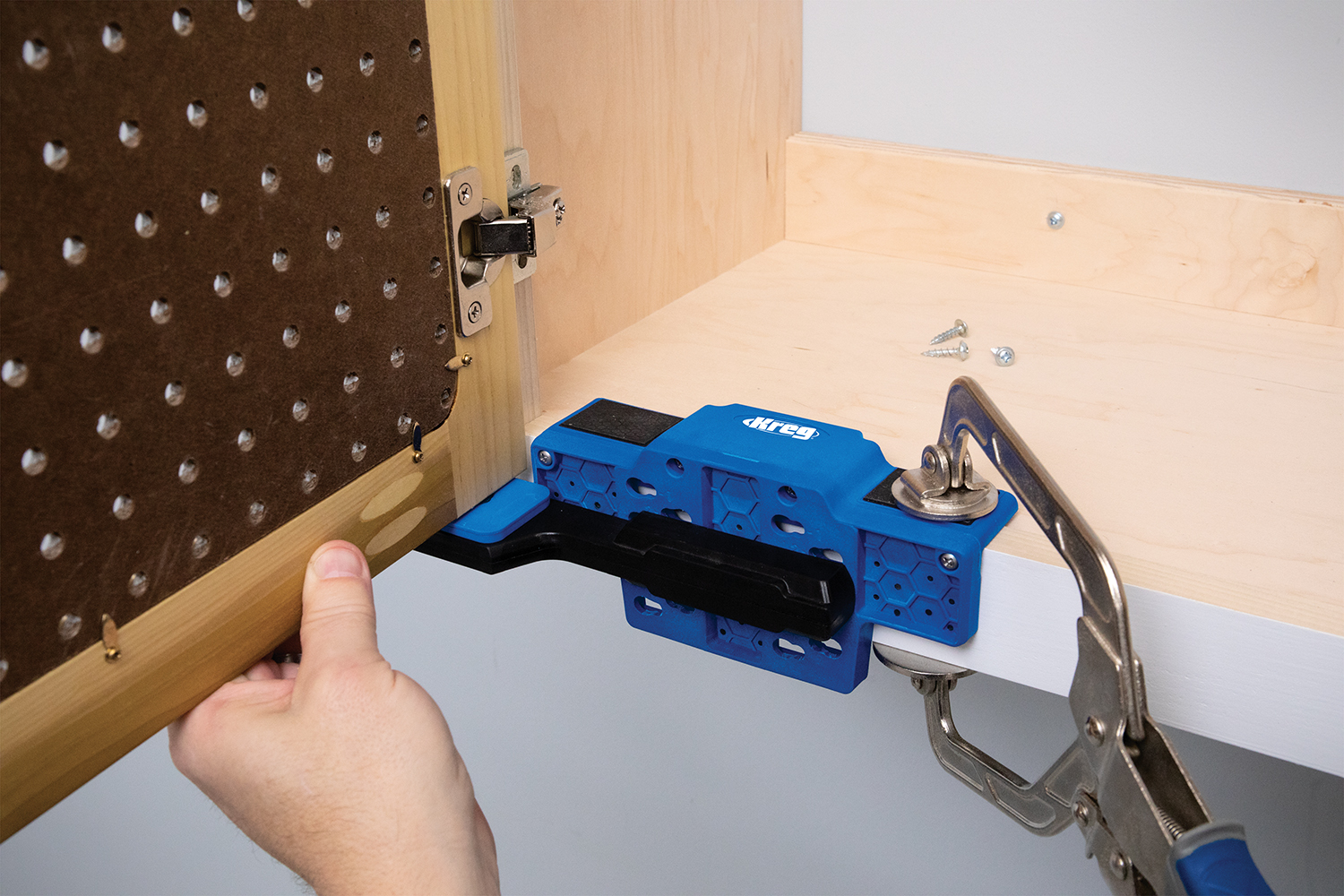

| 2. Drill the Hinge Cups | An image depicting the Kreg Jig securely clamped to the cabinet door, with the drill bit engaged and drilling a hinge cup. | Using the appropriate bit for your hinge type, carefully drill the hinge cups into the door according to the Kreg Jig’s instructions. Ensure the jig is securely clamped to prevent movement during drilling. | Use a slow and steady drilling speed to prevent damage to the door or the jig. |

| 3. Install the Hinge Cups | An image showing a hinge cup being carefully pressed into the drilled hole. | Carefully press the hinge cups into the drilled holes, ensuring they are flush with the door surface. A mallet or similar tool might be necessary for a snug fit. | Avoid forcing the cups, as this can damage the wood or the hinge cup itself. |

| 4. Prepare the Cabinet Frame | An image showing the cabinet frame with the hinge locations marked, and the Kreg Jig being used to create pilot holes for the screws. | Measure and mark the corresponding hinge locations on the cabinet frame. Use the Kreg Jig to create pilot holes for the hinge screws, ensuring proper alignment with the hinge cups on the door. | Accurate measurements are critical for proper door alignment. |

| 5. Attach the Hinges to the Cabinet Frame | An image showing the hinges being attached to the cabinet frame with screws. | Attach the hinges to the cabinet frame using the appropriate screws. Ensure the screws are tightened securely, but avoid over-tightening. | Use the correct screw length to prevent damage to the cabinet. |

| 6. Attach the Door | An image showing the cabinet door being carefully attached to the cabinet frame. | Carefully align the hinge cups on the door with the hinges on the cabinet frame. Close the door to check alignment and adjust as needed. | Ensure the door closes smoothly and without binding. |

Visual Guide for Correct Hinge Placement

A visual guide would include three sections: (1) Correct Hinge Placement: This section would display a correctly installed hinge, showcasing proper spacing, alignment, and depth. (2) Common Mistakes: This section would illustrate common errors such as misaligned hinges, improperly drilled holes, and incorrect screw placement, with clear explanations of how to avoid them. (3) Kreg Jig Usage: This section would visually demonstrate the correct use of the Kreg Jig, emphasizing proper clamping, bit selection, and drilling technique. Each section would use clear, high-quality images or diagrams to illustrate the points effectively. This visual guide would significantly reduce installation errors.

Cabinet Door Hinge Types Compatible with the Kreg Jig

The Kreg Jig is compatible with a variety of cabinet door hinges, including face frame hinges, inset hinges, and overlay hinges. The installation method may vary slightly depending on the hinge type, but the basic principles of using the Kreg Jig for accurate drilling remain consistent. For example, face frame hinges require drilling into the cabinet door and the face frame, while inset hinges require precise placement within the cabinet opening. Overlay hinges require precise placement to ensure proper overlap of the door onto the cabinet frame. The Kreg Jig’s templates and jigs are designed to accommodate these variations.

Comparing Kreg Jig to Alternative Hinge Installation Methods

The Kreg Jig offers a streamlined approach to installing cabinet door hinges, but it’s not the only method available. Traditional methods, while requiring more skill and time, remain viable options. This comparison analyzes the advantages and disadvantages of using a Kreg Jig versus more conventional techniques.

Kreg cabinet door hinge jig – This section provides a detailed comparison of the Kreg Jig method against traditional methods for installing cabinet door hinges, focusing on accuracy, speed, ease of use, and cost-effectiveness.

Kreg Jig versus Traditional Hinge Installation: Advantages and Disadvantages

A direct comparison of the Kreg Jig and traditional methods reveals distinct strengths and weaknesses in each approach. The following lists summarize these key differences, facilitating a more informed decision on the optimal method for a given project.

- Kreg Jig: Advantages

- Increased Accuracy: The jig’s pre-drilled templates ensure precise placement of hinge screws, minimizing errors and improving the final aesthetic.

- Enhanced Speed: The jig significantly reduces installation time compared to hand-drilling and chiseling, particularly for multiple hinges.

- Improved Ease of Use: The jig simplifies the process, making it accessible to less experienced woodworkers.

- Kreg Jig: Disadvantages

- Initial Cost: The jig represents an upfront investment, which may not be cost-effective for infrequent use.

- Limited Application: The jig is specifically designed for certain hinge types and may not be suitable for all applications.

- Space Requirement: The jig requires sufficient workspace for its setup and operation.

- Traditional Methods (Chisel & Hand-Drill): Advantages

- Lower Initial Cost: No specialized tools are required beyond basic hand tools, making it a budget-friendly option.

- Versatility: Traditional methods can adapt to various hinge types and cabinet designs.

- Traditional Methods (Chisel & Hand-Drill): Disadvantages

- Reduced Accuracy: Precise hinge placement relies heavily on the woodworker’s skill and precision, increasing the likelihood of errors.

- Increased Time: Hand-drilling and chiseling are time-consuming, especially for multiple hinges.

- Higher Skill Requirement: Success with this method requires experience and skill in woodworking.

Case Study: Comparing Installation Methods, Kreg cabinet door hinge jig

To illustrate the differences, consider a case study involving the installation of ten hinges on identical cabinet doors. One set of doors uses the Kreg Jig, while the other employs traditional hand-drilling and chiseling.

| Method | Setup Time (minutes) | Installation Time per Hinge (minutes) | Accuracy (measured deviation from planned hinge position in mm) | Total Time (minutes) |

|---|---|---|---|---|

| Kreg Jig | 5 | 2 | 0.2 | 25 |

| Traditional Methods | 2 | 5 | 1.5 | 52 |

This hypothetical example demonstrates the Kreg Jig’s superior speed and accuracy. While setup time is slightly longer for the jig, the significant reduction in installation time per hinge results in an overall faster process. The accuracy data reflects the improved precision of the jig.

Cost-Effectiveness Analysis

The cost-effectiveness of each method depends on several factors. The initial investment for the Kreg Jig needs to be considered against the potential savings in time and reduced risk of errors leading to material waste or needing to redo the work. For a small project, the cost of the Kreg Jig might outweigh the benefits. However, for larger projects or frequent hinge installations, the time saved and increased accuracy make the Kreg Jig a more cost-effective solution.

For example, a professional cabinetmaker installing hinges daily would likely find the Kreg Jig a worthwhile investment due to the significant time savings over the long term. Conversely, a homeowner undertaking a single cabinet project might find the traditional method more economical.

Troubleshooting Common Problems with Kreg Jig Cabinet Door Hinge Installation: Kreg Cabinet Door Hinge Jig

The Kreg Jig, while a popular tool for cabinet door hinge installation, is not immune to issues. Understanding common problems and their solutions can significantly improve accuracy and efficiency. This section details troubleshooting strategies for inaccurate drilling, misaligned hinges, and broken bits, providing both preventative measures and corrective actions.

Inaccurate Drilling

Inaccurate drilling is a frequent problem, leading to misaligned hinges and potential damage to the cabinet door or frame. Several factors contribute to this, including incorrect jig placement, insufficient clamping pressure, and dull drill bits.

Preventative measures include carefully aligning the jig with the hinge markings, ensuring firm clamping to prevent movement during drilling, and using sharp drill bits of the correct size. Regularly inspect your drill bits for wear and replace them as needed. Incorrect bit selection can also lead to problems; always use a bit specifically designed for the material and the jig.

Always double-check the jig’s placement before drilling. Even a slight misalignment can lead to noticeable errors.

Corrective actions for inaccurate drilling can be challenging. If the error is minor, a slight adjustment of the hinge might suffice. However, significant errors may necessitate re-drilling or, in worst-case scenarios, replacing the cabinet door or frame component. Careful planning and precise execution are crucial to avoid this.

Misaligned Hinges

Misaligned hinges result from several factors, including inaccurate drilling, improper hinge placement, and uneven cabinet door or frame surfaces.

Preventing misaligned hinges begins with accurate drilling, as detailed above. Additionally, ensuring the cabinet door and frame are perfectly square and level before installation is crucial. Carefully examine the hinge placement on both the door and the frame, verifying that they align correctly before driving in the screws.

Use a square and level to verify the alignment of the door and frame before installing hinges.

If hinges are misaligned after installation, carefully remove them and re-assess the alignment of the jig and the surfaces. Minor adjustments might be possible; however, significant misalignment will require re-drilling and re-installation.

Broken Drill Bits

Broken drill bits can occur due to excessive force, improper use, or encountering hard spots in the wood.

Prevention involves using the correct drill bit for the material, applying consistent pressure during drilling, and avoiding excessive force. Using a pilot hole, especially in harder woods, can also help prevent bit breakage. Furthermore, always ensure the drill bit is securely clamped in the drill chuck.

Avoid applying excessive pressure when drilling. Let the drill bit do the work.

If a drill bit breaks, it’s crucial to remove the broken piece carefully to avoid further damage. A small, sharp pick or a specialized bit removal tool might be necessary. Always replace broken bits with new, high-quality bits of the appropriate size and type.

Troubleshooting Flowchart

The following describes a flowchart that visually represents the troubleshooting process. The flowchart would begin with a central node representing the problem: “Hinge Installation Problem.” From this node, branches would lead to three sub-nodes representing the three main problem areas: “Inaccurate Drilling,” “Misaligned Hinges,” and “Broken Drill Bit.” Each sub-node would then branch into further nodes representing potential causes (e.g., for “Inaccurate Drilling,” sub-nodes might include “Incorrect Jig Placement,” “Insufficient Clamping,” “Dull Drill Bit”). Each cause would then lead to a solution node (e.g., “Recheck Jig Placement,” “Increase Clamping Pressure,” “Replace Drill Bit”). The flowchart would visually guide the user through the process of identifying the cause of the problem and finding the appropriate solution. This visual representation simplifies the troubleshooting process, allowing for quick identification and resolution of common issues.